SinapTec offers « ready-for-use Ultrasonic modules » integrating the NexTgen remote control technology for easy use and integration that moreover enables our service people to conduct remote diagnostics and updates.

The versatility of our NexTgen-Technology constitues a major advantage, be it for classical applications such as welding, cleaning, cutting, defoaming, manufacturing in heavy-duty environments (temperature, radiation, high pressure, explosion hazard…), be it for special requirements.

Ultrasonic OEM Solutions for the Nuclear Industry

The nuclear sector plays a vital role in electricity production, scientific research, and medicine. Various technologies, including ultrasound, are used to ensure the safety and proper operation of these facilities—for example, during the fuel production cycle (sealing, filtration, cleaning of the active zone, etc.) or during the decommissioning phase and waste treatment (ultrasound-assisted decontamination, etc.).

Ultrasonic applications in the fuel cycle

Ultrasonic applications during decontamination

🔹 Dust removal using acoustic wind

🔹 Descaling of pipelines

🔹 Waste declassification

🔹 Liquid-phase decontamination

🔹 Agglomeration of fine particles for filtration

🔹Cleaning of contaminated surfaces

Cleaning contaminated surfaces in nuclear power plants is a complex and delicate task. Ultrasound can be used to dislodge and remove contamination from various surfaces, including those that are difficult to access. This method avoids the use of harsh chemicals while reducing risks for workers.

🔹Powder management

The technology of our ultrasonic modules is specifically developed for powder treatment, to fluidize and control powder flow, thereby facilitating their transport, dosing, and mixing, as well as the unclogging of hoppers or pipes. This powder management is particularly important to achieve optimal performance of nuclear powders, especially during fuel manufacturing.

Ultrasound OEM Solutions for the Food Industry

Do you manufacture machines for the food industry? Are you looking for solutions to optimize your production processes? Or do you operate bottle and can filling lines in the dairy or brewery sectors? Our technologies are specially designed to meet these needs.

Whether it’s for slicing foods (frozen products, cheeses, cakes), sealing packaging, eliminating foam in beverage and beer production, or cleaning equipment, ultrasound technology stands out as a versatile and effective solution. Its heat-free process helps reduce losses, shorten production times, and increase capacity, while significantly cutting down waste and the use of chemicals—thereby ensuring optimal food safety.

Similarly, for continuous sealing of food packaging, ultrasound ensures strong and leak-proof welds without the risk of heating the packaged product, thereby preserving its integrity.

Ultrasound OEM Solutions for Manufacturing

Textile

Our ultrasound technology is used in the textile industry, particularly for cutting and welding various woven and non-woven materials.

Woven Textiles

🔹 Straps and belts:

For example, seat belts, backpack straps, fashion belts, etc. Ultrasonic cutting ensures clean edges that do not easily fray.

🔹 Technical clothing:

Protective clothing, outdoor sportswear — ultrasonic welding not only improves durability but also preserves comfort and the aesthetic of the garments.

🔹 Sailcloth and tent materials:

For durable outdoor textiles, ultrasonic cutting guarantees burr-free edges and enhances lifespan.

Non-woven Fabrics

🔹 Disposable items:

For diapers, wipes, and surgical gowns, ultrasonic welding ensures reliable sealing and prevents material delamination.

🔹 Filtration materials:

For air filters, liquid filters, etc., ultrasonic welding guarantees the integrity and stability of the filter layer.

🔹 Protective masks:

Ultrasound technology enables fast and effective edge welding, enhancing both wearing comfort and the protective properties of the product.

Plastics

Our ultrasound technology is also used for welding and sealing thermoplastic materials.

It can process a wide range of thermoplastics such as polypropylene (PP), polyethylene (PE), polycarbonate (PC), and ABS to assemble automotive parts, electronic enclosures, and industrial equipment.

For packaging sealing, it ensures that both flexible and rigid packages maintain a strong seal.

Thanks to its versatility, our solution adapts to a wide range of industries:

🔹 Food industry: for packaging such as tea bags, coffee bags, snacks, and cheese.

🔹 Automotive industry: for welding plastic parts like bumpers, lights, and dashboards.

🔹 Cosmetics and personal care: for packaging such as shampoos, masks, and skincare products, ensuring leak-proof seals.

🔹 Medical and pharmaceutical industry: for packaging medical devices, sterile wipes, and pharmaceutical products to guarantee sterility and airtightness.

🔹 Chemical industry: providing moisture and dust resistance for packaging detergents, fertilizers, and horticultural products.

Combining the benefits of welding and sealing, our ultrasonic technology helps our clients optimize their processes, improve product quality, and reduce production costs.

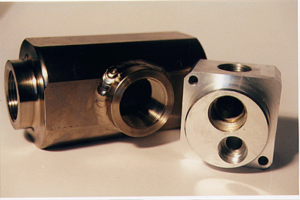

Mechanical parts

In the mechanical sector, SinapTec distinguishes itself with its ultrasonic surface treatment technology, especially in ultrasonic cleaning and ultrasonic spraying, providing efficient and environmentally friendly solutions for metal parts, precision mechanics, and industrial molds.

🔹 Ultrasonic cleaning: Deep removal of contaminants, ideal for machined metal parts, precision components, optical and electronic elements, ensuring residue-free cleaning while reducing the use of chemical solvents for minimal environmental impact.

🔹 Ultrasonic spraying: Enables ultra-fine and uniform atomization, widely used for anti-corrosion coatings, spray lubrication, and functional coatings, improving spray quality while minimizing material waste.

Ultrasound OEM Solutions for Optics

In the field of optics, our ultrasonic cleaning technology is designed to meet the needs of eyewear manufacturers and industries related to optical lenses.

Deep cleaning during the eyewear manufacturing process: at every stage of lens production, ultrasonic cleaning effectively removes oil, grease, abrasives, and dust left by processing, ensuring a clean glass surface and providing a high-quality foundation for subsequent processes.

High-precision surface treatment before coating: Prior to coating, ultrasonic cleaning carefully removes microscopic particles and contaminants from the surface, improving coating uniformity and adhesion, and ensuring optimal optical performance.

Ultrasound Solutions for the Chemical Industry

Ultrasound promotes high-yield chemical reactions by reducing the need for heat, reagents, or catalysts. It is recognized as one of the most effective activation techniques for electrochemical processes and bioprocesses. More broadly, ultrasound contributes to the development of sustainable chemistry and helps minimize effluent production.

SinapTec has developed a solution that enables the implementation of ultrasound technology from laboratory scale to industrial installation.