Ultrasonic cleaning is a vital technology in numerous industries due to its efficiency, precision, and speed. Among the different systems available, the Submersible Ultrasonic Transducer, also known as a Submersible Ultrasonic Box or Submersible Ultrasonic Emitter, stands out for its modularity and ease of integration.

What is a Submersible Ultrasonic Transducer for Industrial Cleaning?

A submersible ultrasonic transducer operates by being completely submerged in a cleaning tank to produce ultrasonic waves.

It consists of a stainless-steel housing with ultrasonic transducers installed inside.

Unlike transducers that are directly bonded to the bottom or walls of a tank, submersible ultrasonic transducers for industrial cleaning are independent modules that can be added or moved as needed. They can also be easily integrated into existing installations.

🔹 Various frequencies are available at SinapTec:

22 kHz, 28 kHz, 40 kHz, 80 kHz, and 100 kHz to suit a wide range of cleaning requirements.

🔹 Specific frequencies are also available on request.

How Does a Submersible Ultrasonic Transducer Work?

The operating principle is based on the emission of ultrasonic waves through a liquid. These waves create a cavitation effect, where microscopic bubbles form and collapse, producing a powerful and uniform cleaning force on immersed surfaces. This action effectively removes impurities, oils, greases, or other contaminants, even in hard-to-reach areas.

Why Choose our Submersible Ultrasonic Transducer for Industrial Cleaning?

🔹 Upgrade Your Existing Cleaning Systems

Our submersible ultrasonic transducers allow you to convert an existing cleaning tank into an ultrasonic bath, avoiding the need for a new machine and reducing both cost and space requirements.

🔹 A Removable Transducer: A Major Advantage

Our submersible ultrasonic boxes are fully removable, offering great flexibility:

Multi-bath usage:

A single unit can be moved from one tank to another, allowing multiple tanks to be equipped with one system.

Better adaptation to complex geometries:

Depending on the shape and layout of the parts, the transducers can be positioned on the sides or bottom of the tank to optimize cleaning efficiency.

Ultrasonic field homogenization:

The ability to reposition the box enables adjustments to ultrasonic wave distribution, ensuring optimal cleaning across all part surfaces.

🔹 100% Custom Design Based on Your Needs

Every industrial environment has its own requirements. Our design office tailors power, frequency, and dimensions to your specific constraints, ensuring efficient and long-lasting cleaning.

🔹 Robust and Durable Design

High-resistance materials:

Built with 3 mm thick stainless steel, the transducer housing provides excellent mechanical and chemical resistance.

Advanced technology:

Our transducers are bonded inside the housing using a high-temperature process, ensuring optimal reliability up to 80°C.

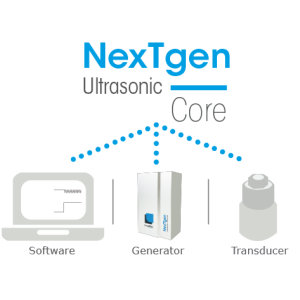

🔹 Compatible with Our NexTgen Generators

Our submersible transducers are operated by our NexTgen ultrasonic generators, ensuring adaptability to various cleaning setups.

Integration of NexTgen Advanced Software

The integration of NexTgen Advanced software enables full traceability of the cleaning process and precise performance diagnostics.

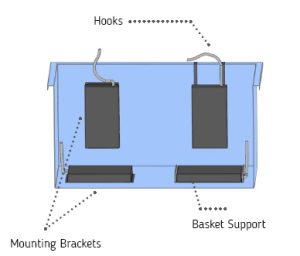

🔹 With Hooks

Hooks allow the unit to be suspended on the side of the ultrasonic tank, offering a simple and adaptable installation.

🔹 With Mounting Brackets

Thanks to mounting brackets, the unit can be securely fixed to the side walls or placed at the bottom of the ultrasonic tank, offering flexible installation to suit your needs.

🔹 With Basket Support

This model includes basket supports, allowing the basket to be optimally positioned at a safe distance from the emitter, protecting the vibrating surface from direct contact.

🔹Simplified Maintenance

Thanks to their modular design, submersible units can be replaced quickly and easily, minimizing downtime and simplifying maintenance.

Applications of Submersible Ultrasonic Transducers in Industry

Our submersible transducers for industrial cleaning are used across various sectors:

🔹 Medical Industry: Cleaning of surgical instruments and implants

🔹 Optical Sector: Precision cleaning of ophthalmic lenses and optics

🔹 Automotive and Aerospace: Degreasing and decontamination of mechanical components

🔹 Food Industry: Cleaning of conveyors and production utensils

🔹 Nuclear Sector: Liquid-phase cleaning, especially for radioactive particle decontamination

End-to-End Support for Successful Integration

Implementing an ultrasonic solution requires technical expertise. SinapTec supports you with:

🔹 Drafting technical specifications in collaboration with your teams to clearly define needs

🔹 Custom equipment design and adaptation based on your specific application requirements

🔹 Training for equipment operation and implementation to ensure effective use

🔹 Support for equipment configuration and operation protocols to ensure optimal performance and simplified maintenance

📌 Need a tailored solution?

Contact us to learn more about our submersible ultrasonic transducer solutions and how they can enhance your industrial cleaning processes.

Or would you like to explore other ultrasonic cleaning solutions?