Notre générateur ultrasons Inside est une solution électronique compacte, numérique et performante, conçue pour une intégration directe dans vos équipements industriels.

Équipé de la technologie brevetée NexTgen, ce système 100% numérique offre un pilotage précis des transducteurs (de quelques kHz à 100 kHz, jusqu’à 2000 W), une supervision à distance par une liaison Ethernet. Il s’adapte aisément à des applications variées comme le nettoyage, le dégazage, l’homogénéisation, l’émulsification ou encore la découpe, le soudage ultrasonique…

What is an ultrasonic generator?

An ultrasonic generator is a device that converts a supply voltage (mains 230V or low voltage 24V) into a higher-frequency electrical signal ranging from 10 kHz to 5 MHz.

It is paired with an ultrasonic transducer, whose role is to convert the high-frequency electrical signal produced by the generator into mechanical vibration. This mechanical vibration is then transmitted into a medium depending on the final application.

Our Inside ultrasonic generators: compact, powerful, and smart

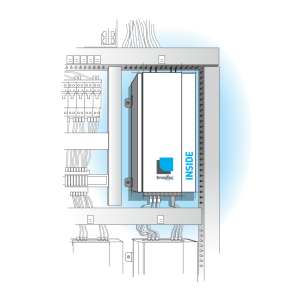

The Inside ultrasonic generator range has been developed to meet the demands of industrial environments. Our Inside ultrasonic generator allows simple and fast integration into your production lines. Thanks to its compact design, advanced connectivity, and digital control, it can be easily integrated into any type of automated system.

🔹 Cabinet integration

🔹 Ethernet / RS485 communication

🔹 Remote diagnostics and updates

🔹 Operating safety

🔹 Embedded intelligence

➡️ This model is part of our ultrasonic generator range, offering optimized solutions for every need.

Our Inside models: power levels and associated uses

Our Inside generators cover a wide range of power levels suited to different industrial applications:

🔹 INSIDE30: up to 30 W for very low-power applications such as spraying and sample preparation

🔹 INSIDE150: up to 150 W, ideal for small-volume degassing

🔹 INSIDE500: up to 500 W, suitable for emulsification and homogenization

🔹 INSIDE1500: up to 1500 W continuous (3000 W peak), perfect for cleaning, sieving, and unclogging

🔹 INSIDE2000/3000: up to 3000 W in pulsed mode, optimized for thermoplastic welding and ultrasonic cutting

This complete range meets all industrial needs in ultrasonic processing, from the smallest volumes to the most demanding processes. Whatever your industrial field, our Inside ultrasonic generator adapts to your performance requirements. Each Inside ultrasonic generator is designed to ensure reliability, power, and stability, even in the most demanding industrial environments.

👉 Our experts can guide you toward the model best suited to your needs.

Customized ultrasonic solutions for your specific needs

Our Inside ultrasonic generators can be delivered pre-integrated in an electrical cabinet, upon request, for faster and safer implementation in your industrial environment.

This flexibility makes it easy to integrate the Inside ultrasonic generator into automated or semi-automated production lines.

➡️ Contact us to learn more.

The technical advantages of inside ultrasonic generator

🔹 Equipped with patented NexTgen technology.

🔹 NexTgen Inside generators integrate easily into many environments thanks to their compact footprint.

🔹 They are protected against voltage, current, frequency, and temperature drifts, and come with a 2-year warranty.

🔹 Various control interfaces are available to ensure perfect integration into your process and guarantee full traceability.

🔹 Frequency and power are self-regulated to ensure the stability of the ultrasonic process.

🔹 Generator and transducer parameters can be monitored and diagnosed remotely via a local Internet connection.

Two configurations suited to ultrasonic cleaning

🔹Classic configuration :

This configuration includes a dry-contact input for starting /stopping the cleaning and a fault output.

🔹Process configuration :

The additional functions, usually handled by external modules, are directly integrated into the generator:

- Power setpoint and mesurement via 0-10V

- Bath temperature control

- Mode selection(normal, degassing, frequency modulation)

- Water level monitoring

Advanced Connectivity: Ethernet & RS485

They incorporate standard industrial communication protocols…

Our ultrasonic generator includes standard industrial communication protocols (Ethernet and RS485), enabling:

🔹 Full control via PLC or operator interface

🔹 Precise management of ultrasonic cycles

🔹 Real-time monitoring of frequency and power

🔹 Access to advanced diagnostic functions

This connectivity ensures optimal integration into your industrial environment and efficient supervision of your ultrasonic processes.

NexTgen Software: a Central Interface for Control, Traceability and Optimization

For any application (cleaning, welding, etc.), the NexTgen software plays a key role in operating Inside ultrasonic generators. It enables users to configure, monitor, and optimize generator parameters in real time, while ensuring complete traceability of operations.

Available in two versions, it adapts to all levels of requirements—from basic adjustments to advanced control of industrial processes. It was specifically designed to unlock the full potential of the Inside ultrasonic generator and optimize its performance in real time.

🔹 NexTgen Start (free version)

-

Timer and power adjustment

-

Real-time visualization of generator status (temperature, frequency, power, etc.)

→ Ideal for standard operations or testing phases.

🔹 NexTgen Advanced

-

Access to advanced configuration, monitoring, and traceability features

-

Control of complex parameters and export of operating data

→ Ideal for integration into demanding industrial environments and applications requiring fine-grained supervision.

Any questions? Need a demonstration?

Our experts are available to answer all your technical questions.

Contact us today!