Introduction

In ultrasonic cleaning equipment, the available space for integrating the generator can be limited due to the machine design, its function, or the application. This constraint makes it necessary to choose a compact solution while ensuring stable operation to guarantee repeatable cleaning cycles. Traditional ultrasonic generators are often bulky and not always suited to these configurations.

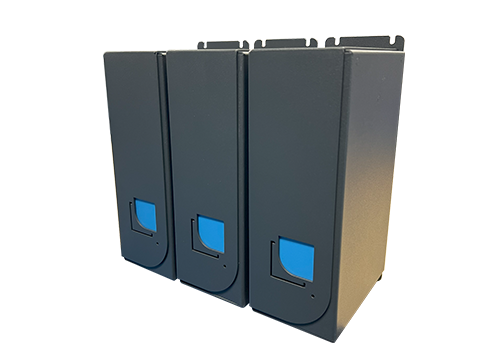

To meet these needs, SinapTec developed the Imbed 200, a compact ultrasonic generator designed for industrial equipment requiring up to 400 Wpeak in a reduced footprint. Thanks to its embedded NexTgen® technology, the Imbed 200 provides operational stability and automatic adaptation to variations in cleaning cycles, ensuring consistent performance.

Minimal footprint for easier integration

One of the main advantages of the Imbed 200 is its compact format: 130 × 235 × 75 mm.

This reduced size enables easy integration into:

🔹 An electrical cabinet,

🔹 A dedicated housing,

🔹 A machine where space is limited.

This compactness makes it possible to:

🔹 Reduce the overall footprint of the machine,

🔹 Optimize the internal architecture of ultrasonic cleaning equipment,

🔹 Facilitate integration into modular or multi-tank systems, when several generators must be installed in a confined space.

For manufacturers of industrial ultrasonic cleaning equipment, this reduced footprint is a major advantage both during the design phase and during industrialization.

Flexibility suited to a wide range of ultrasonic cleaning configurations

Despite its small size, the Imbed 200 offers high flexibility to meet industrial cleaning requirements:

The generator enables:

🔹 Multiple ultrasonic operating modes,

🔹 Control of 1 to 4 ultrasonic transducers,

🔹 Adaptation to different tank sizes and cleaning geometries.

Integration and investment costs are therefore optimized, which is especially appreciated in OEM projects or automated cleaning lines.

Embedded intelligence to ensure process stability

The Imbed 200 integrates embedded NexTgen® technology, developed and patented by SinapTec. This advanced electronic platform plays a key role in controlling ultrasonic cleaning processes.

Thanks to this embedded intelligence, the generator can:

🔹 Automatically adapt to load variations,

🔹 Analyze transducer impedance,

🔹 Program generator operating parameters—especially frequency and power—according to the process.

In industrial applications, where consistent results are essential, this automatic adaptation helps ensure uniform cleaning quality even when operating conditions change (liquid level variations, transducer aging, load changes).

Integrated software: connectivity, control, traceability, and diagnostics with NexTgen®

The intelligent functions of the Imbed 200 rely on the NexTgen® software platform (part of SinapTec’s patented NexTgen® concept), enabling advanced use of the generator in ultrasonic cleaning applications.

This software platform allows you to:

🔹 Optimize ultrasonic cleaning cycle parameters,

🔹 Ensure precise operational control,

🔹 Guarantee traceability of cycles, faults, and parameters,

🔹 Perform diagnostics on both the transducer and the generator.

These features facilitate process monitoring, maintenance, and operation of industrial ultrasonic cleaning equipment.

Two levels of software features

To address different operational needs, the Imbed 200 offers two software feature levels based on the NexTgen® platform.

Start Version (included)

The Start version enables:

- Ultrasonic power adjustment,

- Operating time management,

- Selection of up to 8 control modes (regulated, modulated, sweep or random frequency, continuous or pulse operation…),

- Transducer diagnostics.

This version is particularly suited to ultrasonic cleaning applications requiring a simple and efficient setup.

Advanced Version (optional)

The Advanced version adds additional features:

- History of cycles, faults, and parameters,

- Graphical visualization,

- Data backup.

These functions support process monitoring, maintenance, traceability, and operation of industrial cleaning equipment.

Discover the NexTgen® software platform for our ultrasonic generators.

Two technical configurations: Classic and Process

To match different automation levels in industrial cleaning equipment, the Imbed 200 is available in two configurations: Classic and Process.

Classic configuration

The Classic version includes:

🔹 A dry-contact input,

🔹 A fault relay output.

It is perfectly suited to standalone ultrasonic cleaning systems or equipment requiring a simple control interface.

Process configuration

The Process version includes all Classic features and adds:

🔹 A 0–10 V power setpoint and power feedback signal,

🔹 A 10 V DC supply for a potentiometer,

🔹 A mode-selection switch,

🔹 A configurable relay output.

This configuration is ideal for automated cleaning lines, where the ultrasonic generator must be fully integrated into the process control system.

A communication-ready solution for industrial equipment

The Imbed 200 is designed for easy integration into modern industrial environments thanks to its communication capabilities.

The generator includes:

🔹 RS485 communication (optional),

🔹 Compatibility with PC software,

🔹 The ability to operate autonomously or under PLC control.

These functions enable centralized supervision, simplified configuration, and easier maintenance of industrial ultrasonic cleaning systems.

A preferred solution for OEM projects

The Imbed 200 is already widely used in OEM ultrasonic cleaning projects. SinapTec supports many industrial equipment manufacturers by providing compact, reliable ultrasonic generators perfectly suited for embedded integration.

With its expertise in power electronics dedicated to ultrasonic applications, SinapTec offers:

🔹OEM solutions tailored to machine-specific constraints,

🔹Technical support throughout industrial projects,

🔹Long-term availability of our technologies.

Conclusion

The Imbed 200 is a compact ultrasonic generator designed for industrial ultrasonic cleaning applications where space is limited. Thanks to its flexibility, embedded intelligence, and integration capabilities, it meets the requirements of industrial cleaning equipment.

Contact our teams to assess whether the Imbed 200 is the right fit for your machine and to define the most suitable configuration.