Do you have a question about any of the products below? Need a quote or more information?

Introduction

SinapTec is a trusted technology partner for machine manufacturers and system integrators looking to implement a high-performance, reliable, and scalable ultrasonic welding solution in their equipment.

As a designer and manufacturer of ultrasonic equipment, we develop and supply OEM modules, generators, transducers, and sonotrodes tailored to the demands of industrial production lines. Our solutions are flexible, compact, and easy to integrate, enabling seamless adaptation to your machines while ensuring maximum efficiency.

Whether you’re designing machines for the automotive, medical, electronics, packaging, or technical textiles industries, SinapTec provides you with a turnkey solution and personalized support tailored to your needs.

Components for Ultrasonic Welding

Ultrasonic welding uses high-frequency vibrations to generate heat at the joint in a very short time. These localized vibrations create linear friction, which, combined with applied force, produces a molecular bond at the welded joint.

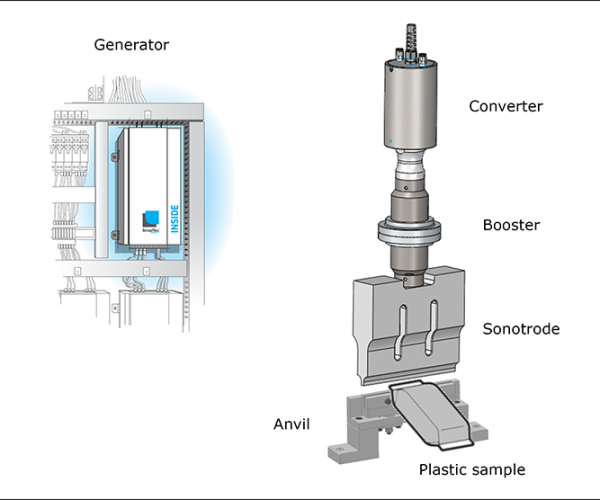

There are many models and combinations of ultrasonic welding machines to meet the needs of various industries. However, all of them share the following five core components:

🔹The generator converts standard European or North American mains power (230 V ± 50 Hz) into a sinusoidal signal between 20 and 70 kHz, suitable for the transducer and proportional in amplitude to the desired vibration output. Depending on the application, the generator can deliver power ranging from a few watts to over 3,000 watts.

🔹The converter transforms the electrical energy received from the generator into mechanical energy in the form of high-frequency vertical vibrations. It uses the piezoelectric effect, producing electrical polarity when a crystalline substance is compressed.

🔹The booster is a mechanical transformer that amplifies or reduces the vibration amplitude applied to the welded parts via the sonotrode. It is tuned to resonate at the same frequency as the converter it pairs with.

🔹The sonotrode is selected or designed for a specific application. Each sonotrode is finely tuned to uniformly apply the required vibrations to the plastic parts being welded.

🔹The anvil serves as a counter-tool. It features specific markings to concentrate the vibrations from the sonotrode and ensure optimal weld quality.

Benefits of Ultrasonic Welding

Ultrasonic welding is a key solution for assembling thermoplastic materials and certain metals. This technology relies on the application of high-frequency ultrasonic vibrations that generate localized fusion, creating strong and durable bonds.

Why choose ultrasonic welding?

🔹Speed and efficiency: The welding process is fast, enabling increased productivity. Parts can be assembled in just a few seconds.

🔹No need for additional materials: Unlike other welding methods requiring adhesives, glues, or fasteners, ultrasonic welding often joins parts without any extra materials.

🔹Clean and eco-friendly: Ultrasonic welding generally produces no waste or fumes, making it a clean and environmentally friendly method.

🔹High bond strength: Ultrasonically welded joints tend to be extremely strong—often as strong as or stronger than the base materials.

🔹Precise process control: Welding parameters such as vibration amplitude and applied pressure can be finely tuned to ensure consistent, high-quality results.

🔹Versatility: Ultrasonic welding can be used with various materials, including plastics, metals, and certain composites.

🔹Cost-effectiveness: While ultrasonic welding equipment may require an initial investment, the per-joint cost is often very competitive due to the speed and efficiency of the process.

In short, ultrasonic welding is often chosen for its speed, cleanliness, bond strength, and versatility, making it an attractive solution for many industrial applications.

Standard OEM Ultrasonic Welding Module: The High-Performance Solution for Machine Builders

At SinapTec, we develop OEM modules for seamless and efficient integration into your equipment. Our modules are designed to meet the needs of machine builders and integrators looking to add ultrasonic welding solutions to their production lines.

We specialize in designing, manufacturing, and supplying standard, customized, and modified ultrasonic modules, including generators, transducers, and welding sonotrodes.

Features of SinapTec Welding Modules:

🔹Optimized power: Our generators ensure stable and efficient ultrasonic energy transmission.

🔹Compact design: At equivalent power levels, our ultrasonic generators are among the most compact on the market.

🔹Flexibility: Settings can be adjusted to fit your production needs.

🔹Advanced technology: Custom-designed sonotrodes to maximize welding performance and adapt to various weld joint geometries.

🔹Lower production costs: No need for additional assembly materials (glue, rivets, screws).

🔹Reduced waste: Clean process with no residue or consumables.

🔹Enhanced reliability: Our equipment is designed for intensive use with minimal maintenance. Our generators and converters have been tested over millions of cycles to ensure repeatable welding operations and robust performance.

🔹Compliance with industrial standards: Our technologies meet the highest quality and safety standards.

Our OEM modules are the ideal solution for manufacturers seeking to integrate a reliable, high-performance, and scalable welding technology into their machines.

By choosing SinapTec solutions, you ensure more efficient, cost-effective, and environmentally friendly production.

Technical Support and Personalized Expertise

Our ultrasonic welding systems are designed to meet all industrial requirements. SinapTec offers manufacturers:

🔹High-precision ultrasonic generators for optimal energy control

🔹Custom transducers and sonotrodes tailored to your application

🔹Automated welding solutions that can be integrated into existing production lines

🔹Scalable equipment to optimize performance over time

Thanks to our R&D expertise, we develop innovative solutions to meet tomorrow’s technological challenges.

Stay Ahead of the Competition

In a constantly evolving industrial market, adopting SinapTec’s ultrasonic technology helps you remain competitive:

🔹Boost productivity with fast and efficient technology

🔹Ensure flawless quality with clean and consistent welds

🔹Optimize manufacturing costs by reducing waste and maintenance

Investing in our ultrasonic welding solutions means choosing a reliable, durable, and future-ready technology.

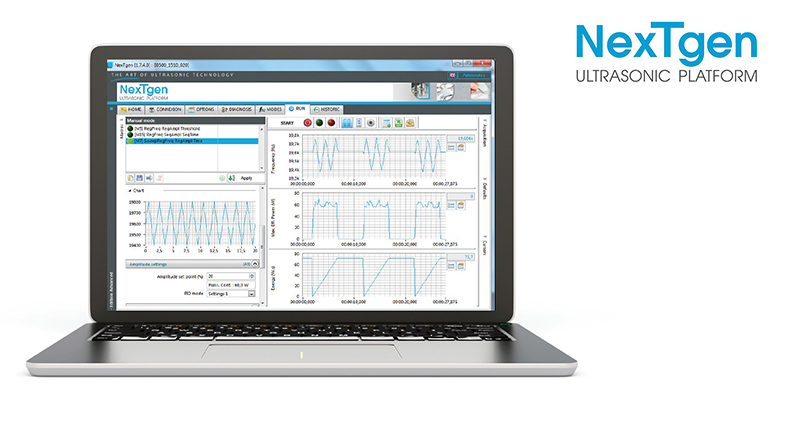

Take Control of Your Process with NexTgen Software

For complete control and optimized management, our NexTgen software allows you to:

🔹Adjust welding parameters in real-time for optimal precision

🔹Monitor and record performance data to improve traceability

🔹Optimize production settings for better energy efficiency

🔹Manage all SinapTec equipment via an intuitive interface

With NexTgen, you maintain complete control over your processes and maximize production quality and efficiency.